Which Materials Are Suitable For Manufacturers To Forge?

CXIN Forging is a place where innovation and precision meet to reshape the landscape of forging excellence. CXIN is a renowned forging company that provides bespoke solutions designed with the right combination of heritage and cutting-edge technology.

CXIN brings forth a devotion to unparalleled craftsmanship, with a tradition strongly entrenched in the age-old skill of forging. Our cutting-edge facilities combine time-tested processes with cutting-edge engineering to ensure that every forged part we manufacture is a testament to strength, durability, and precision.

CXIN Forging thrives on challenges, serving industries ranging from aerospace to automotive. Our skills extend beyond metal shaping; we establish partnerships based on trust and dependability. Visit the manufacturer’s website for more details. Our method is built on careful material selection, innovative forging processes, and severe quality controls, ensuring that our clients receive components that exceed the most stringent industry standards.

An Indestructible Handbook of Materials in the Forging Industry

Forging stands out as a time-honored technique for shaping metals into strong and precision-engineered components in the fast-paced world of production. The forging process’s versatility stems not only from its ability to create complicated designs but also from its compatibility with a wide range of materials. This article examines the many materials that manufacturers can forge, as well as their features and applications.

Steel: The Backbone of Forging

Steel is a key material in forging because of its strength, durability, and adaptability. Forging carbon steel, alloy steel, and stainless steel components for automotive, construction, and industrial uses is common. The forging process improves steel’s intrinsic properties, resulting in products with improved mechanical properties.

Aluminum: Lightweight and Formidable

Aluminum is used in industries that require a balance of strength and weight since it is lightweight and corrosion-resistant. Aluminum alloys are strengthened by forging, making them perfect for aerospace, automotive, and marine applications where weight reduction is crucial.

Titanium: Forging Innovation in Aerospace

Titanium is a popular material in aerospace and medicine due to its excellent strength-to-weight ratio and corrosion resistance. Forging titanium components ensures their resistance to intense temperatures, making them essential for aircraft, spacecraft, and medical implants.

Copper and Copper Alloys: Conductivity and Adaptability

Copper is forged into components for electrical and electronic applications because of its great electrical conductivity. Copper alloys such as brass and bronze are also used in forging because they combine conductivity, corrosion resistance, and aesthetic appeal.

Nickel Alloys: Resilience in Extreme Environments

Nickel alloys are widely used in aircraft, chemical processing, and power generation because of their durability in high temperatures and harsh conditions. Forging improves their mechanical qualities, making them ideal for use in harsh environments.

Exotic Alloys: Pushing the Boundaries of Engineering

Exotic alloys such as Inconel and Monel are forced to endure harsh conditions in cutting-edge industries such as nuclear and defense. These alloys are indispensable in specialized applications due to their unique mix of heat resistance, corrosion resistance, and mechanical strength.

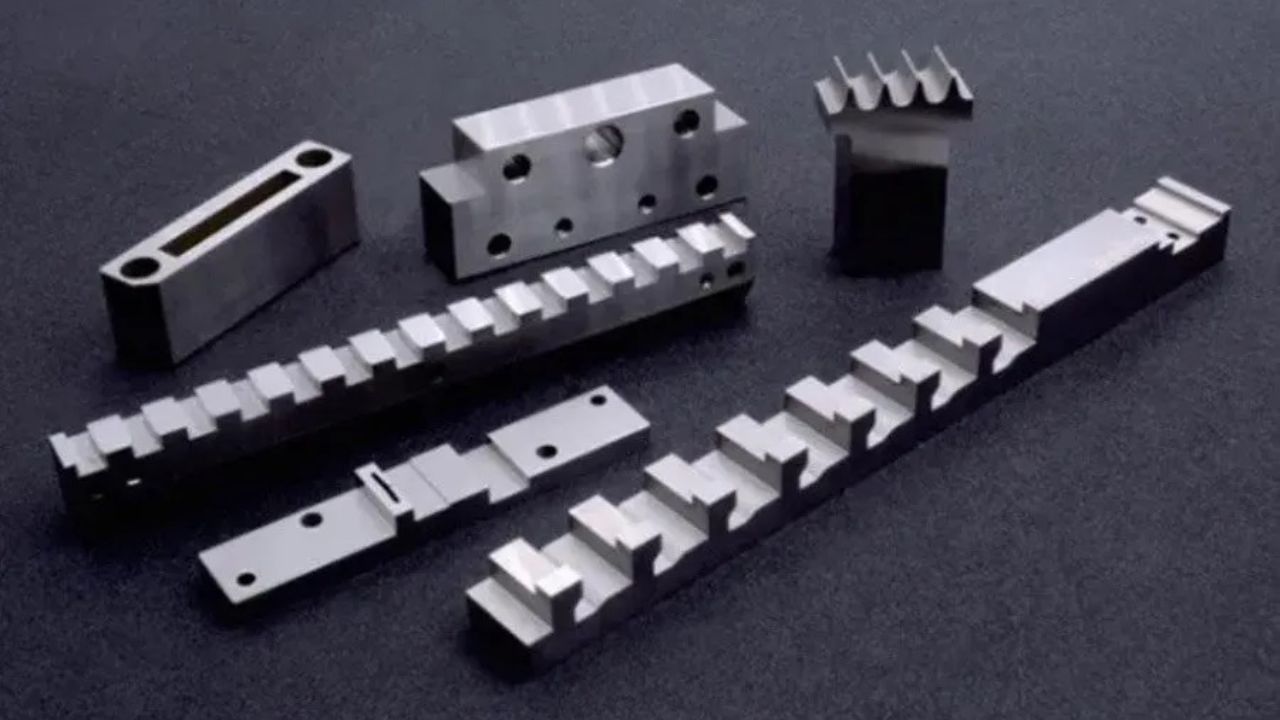

Tool Steels: Precision Forging for Cutting Tools

Precision forging is used to make cutting tools and dies from tool steels, which are noted for their hardness and wear resilience. Forging refines the microstructure of tool steels, ensuring sharpness, durability, and dependability in demanding machining applications.

Super Alloys: Forging for High-Performance Applications

Hastelloy and Waspaloy super alloys are forged to survive harsh chemical conditions and high temperatures. These alloys are used in aircraft, chemical processing, and power generation, where corrosion and oxidation resistance are critical.

Final Words

The ability to deal with a varied range of materials emphasizes the adaptability and relevance of this age-old manufacturing method in the modern world of forging. Forging is a cornerstone of modern engineering, always pushing the frontiers of what is possible in the manufacture of durable and high-performance components, from steadfast steel to the imaginative usage of unusual alloys. Forging’s adaptability ensures that it will remain an indispensable process for manufacturing the materials of the future as industries grow.