How to Differentiate Between HTD and GT Timing Belts

When a timing belt is used in industrial power transmission systems, the timing belt selection option can be a major factor in determining efficiency, noise level, and the performance of the system. The two most varied types are commonly compared, that is, GT (Gates Tooth) and HTD Timing Belts. Though they might seem to be the same in their structure, each type is different in terms of tooth structure, load-carrying capacity, and suitability for application. The knowledge of these differences can also be used by engineers and manufacturers to identify the correct belt to use for their needs to guarantee reliability and accuracy in their functions.

Introduction to Timing Belt Technology

A synchronous drive system is also closely connected with timing belts, and it is necessary to keep the ratio of the pace of the pulleys constant. In contrast to V-belts or flat belts, timing belts have teeth that fit into matching grooves on pulleys, positively engaging so that they do not slip. It is possible to have accurate timing, high torque transmission, and high mechanical efficiency. The technology of timing belts has, over the years, been upgraded to suit the rising needs of a quieter operation, longer time of life span, and more torque. The two key achievements in the history of the modern synchronous belt are the HTD and GT series among these innovations.

HTD Timing Belts: Design and Performance

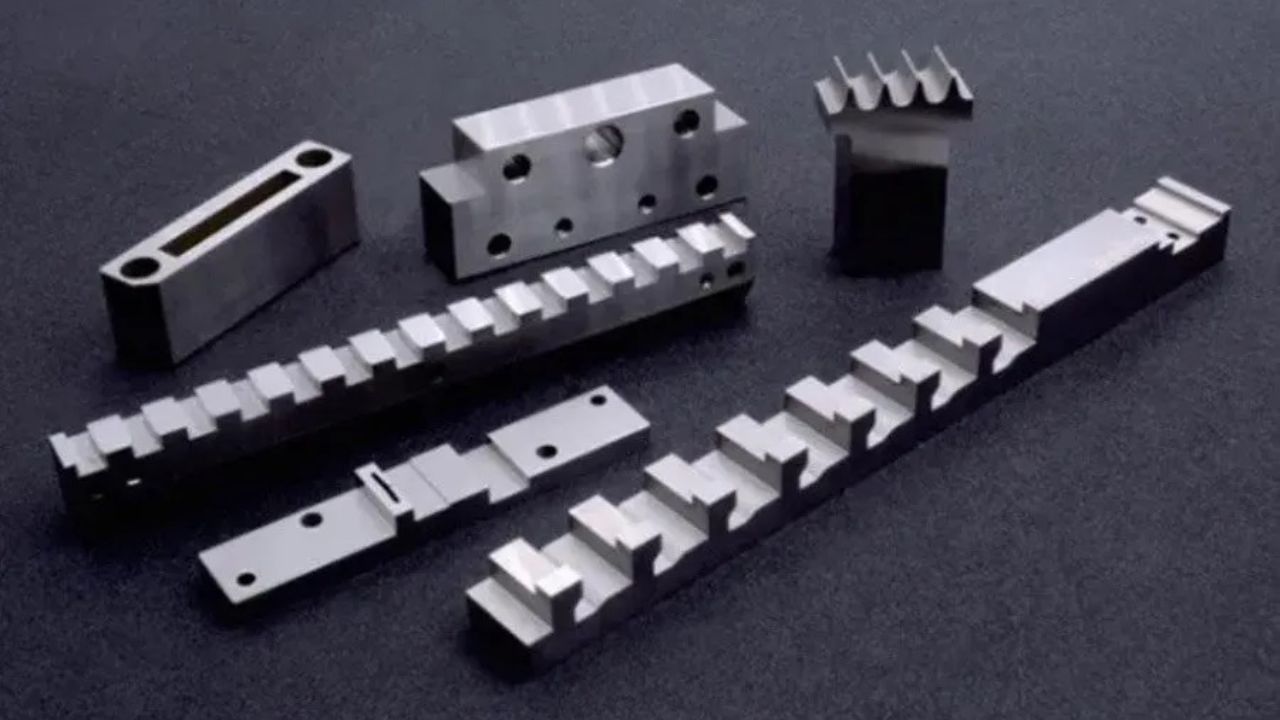

To enhance the existing tooth pulleys that were likely to wear and restrict the impartation of torque, HTD (High Torque Drive) timing belts were developed. The tooth shape in the HTD profile is more rounded, thus the stress is distributed better, and the shearing of the teeth is reduced with heavy loads. This design increases the power transmission capacity, and thus HTD belts can be used in high torque systems like industrial machinery, robotics, and automotive systems.

Standard Pitches

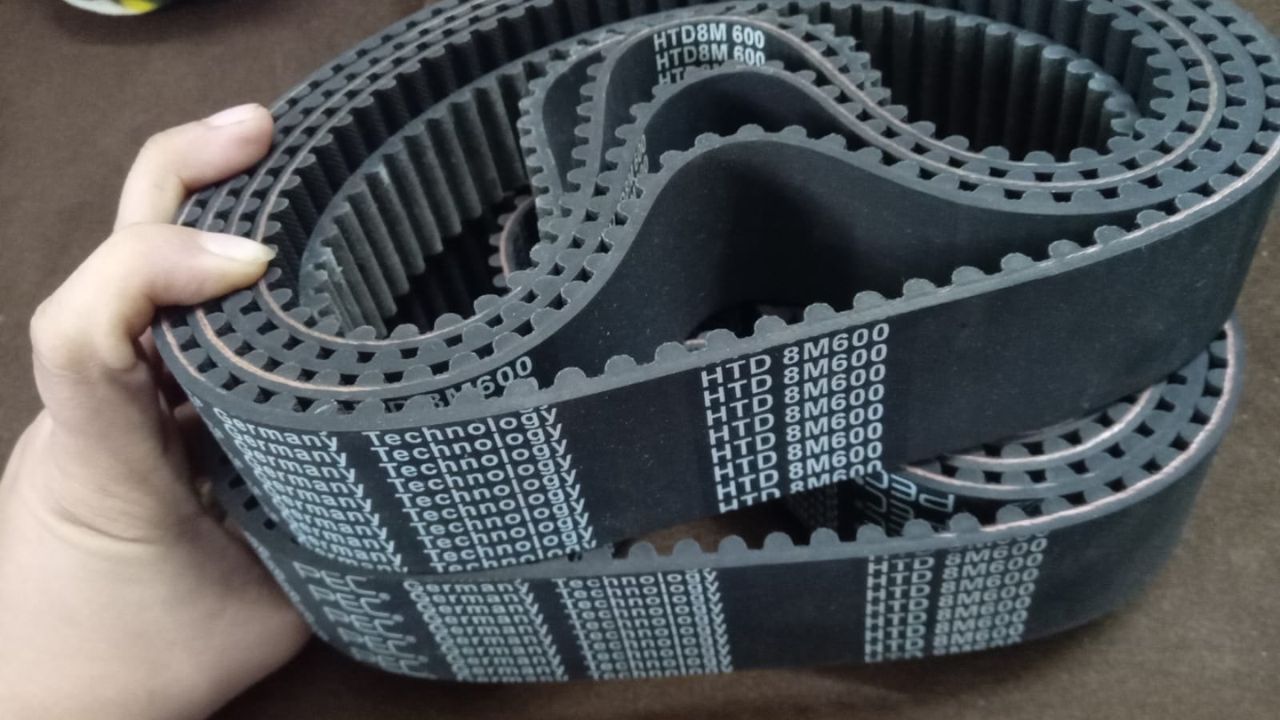

The HTD profile is widely offered in standard pitches like 8M, 14M, and 20M, where the number represents the pitch difference between the adjacent teeth in millimeters. The material of such belts is most often rubber or polyurethane with fiberglass or steel cord reinforcement to provide the balance of strength and flexibility. But although HTD belts have very strong torque-handling characteristics, they are more likely to produce noise and vibration than newer belt designs. The shape of the rounded teeth, more robust than the older trapezoidal form, does not work as well with the pulley, causing small oscillations and reduced performance in a high-speed or high-precision system.

GT Timing Belts: The New Generation

GT (Gates Tooth) timing belts, also known as Power Grip GT or GT3 belts, are a further development of synchronous belt technology. They were meant to overcome the weakness of the HTD systems by offering a more sophisticated tooth geometry. The GT profile has a curved profile with optimized tooth engagement, enabling the profile to engage in the meshing process of the pulley with lower backlash.

This compacted shape of teeth is not only efficient in power transmission, but it also reduces the levels of stress concentration on a specific tooth. Consequently, GT belts have a longer operation, low noise, and high load carrying capacity compared to other HTD belts of the same pitch. The enhanced design also minimizes heat accumulation when operating, which is important in ensuring dimensional stability and increasing service life in high-speed applications.

Comparison of Holt HTD and GT Timing Belts

Although both HTD and GT belts fall under the category of curvilinear synchronous belts, their difference is mainly based on the tooth geometry, engagement dynamics, and focus on application. The HTD belt is marked with a deeper and rounder tooth, which offers good transmission of torque in heavy-duty applications. Nevertheless, its interaction is not as sophisticated, and thus, there is an increase in noise and wear when continuously operated.

Unlike that, the GT belt has a more accurate and asymmetrical tooth that guarantees progressive engagement and release with the least friction. This is efficient as well as enabling the suitability of GT belts to high-speed and low-vibratory environments. The performance perspective of GT belts is that they tend to provide higher torque capacity and lifespan at the same load environment.

Choosing the Right Belt for the Application

Use of HTD and GT timing belts is dependent on the nature of the operations of the system. The HTD belt is also affordable and dependable in cases where high torque, durability, and moderate accuracy are required, like in conveyors, compressors, or industrial equipment. Nevertheless, GT belts are preferable in cases where accuracy in positioning, low noise operation, and high efficiency are critical.

Conclusion

To sum up, though the modern synchronous drive systems have their roots in HTD belts, GT belts have made efficiency and precision a step ahead. Each has its role to play in the industrial and mechanical applications, and the correct choice can significantly improve the performance, cost, and life of the system. The knowledge of the basic disparities in the use of HTD and GT belts enables the engineers to make wise decisions that enhance performance, lessen upkeep, and stability of the power transmission systems in the long run.