Stamping press equipment is also needed in the manufacturing world to create precise, repeatable, and highly efficient parts. These instruments must withstand constant pressure, friction, and impact during the stamping process. Following this reason, toolmakers and manufacturers tend to use tungsten carbide as opposed to other materials. It also has outstanding mechanical strength, hardness, and durability; hence, it is a better component in industries that require precision. To understand why tungsten carbide is suitable for stamping die punches and tools, it is necessary to understand its numerous applications in the electronics industry, automotive, connector terminals, and other high-precision industries.

Outstanding Intensity and Wear Resistance

This is a very hard material, second only to diamond in hardness. This hardness enables the tungsten carbide tools to retain their cutting edges even when the tools are subjected to great pressure. Punch tips and the die surfaces need to be hard when stamping is done constantly on metal sheets. Tungsten carbide allows the tool to be maintained in accurate operation without wearing out during extended periods of production. This long life span not only enhances the quality of the product, but also lowers the replacement rate of the tools and the manufacturing cost.

Excellence of Strength: High Pressure

The stamping press tools are subject to extremely high forces throughout a cycle. The compressive strength of tungsten carbide is very high, and it is able to sustain such loads without cracking or deformation. Although a number of tool steels might perform excellently at first, they start to oxidize because of repetition. Tungsten carbide is a material that is stable even in severe working conditions. Its capacity to maintain its shape and structural strength guarantees its consistent performance during the high-volume stamping processes. This is particularly useful in manufacturing small or complicated parts, where any slight variation may jeopardize the accuracy of the parts.

Heat and Friction Resistance

Friction between the tool and the metal sheet accumulates heat during stamping. Overheating may lead to the destruction of the pre-prepared tool materials, which will become soft or lose their edges. Tungsten carbide has high heat resistance such that it does not soften even when used under thermal pressure. This feature renders it especially useful in heavy stamping or high-speed stamping. Tungsten carbide tools are more reliable, have a longer life, and are more precise due to the lower chances of thermal damage.

Precision Work Dimensional Stability

Accuracy is a condition that cannot be compromised in the electronics, mobile phone, computer, and connector manufacturing industries. These industries require almost every slight change in the size of punches to create flawed components. Tungsten Carbide offers excellent dimensional stability, enabling punches and dies to retain the same measurements. It has a small coefficient of thermal expansion, which means that the size would not change much even when the production lasted a long time. This stability is necessary where the project has ultra-tight tolerances and repeatability.

Corrosion and Resistance to Chemicals

The stamping processes occasionally contain some lubricants, cooling fluids, or environmental conditions that can be causes of corrosion. The chemical resistance of tungsten carbide guards it against these possible dangers. Tungsten carbide is also structurally stable as opposed to some types of steel materials that corrode or oxidize with time. This resistance improves the life of the tools and adds to the competent long-term performance. It also minimizes maintenance needs, and this guarantees a smooth workflow in stamping workshops.

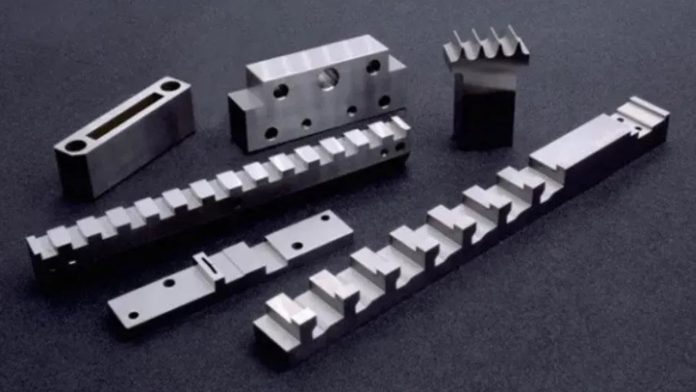

Flexibility in Stamping Processes

Various industries depend on different stamping press equipment, which includes cutting punches, forming punches, die inserts, and precision components. The versatility of tungsten carbide has made it very effective in all these applications. The material can be used to support complex machining and still be accurate, whether one needs standard cylindrical punches or a rectangular shape of a specific size. Optical profile grinding and precision surface grinding are among the technologies that increase its final performance, thus making it suitable for the manufacturing of ultra-fine details and sharp edges.

Economy in Cost

Tungsten carbide tools are also costly, although their life cycle will be much longer, and they will offer great cost benefits. The manufacturers have the advantage of fewer replacements, less downtime, and quality output. Tungsten carbide is an effective solution that is cost-effective in the long term because it offers a high rate of productivity and precision to any business. In the long run, the downtime, maintenance, and higher durability greatly offset the initial investment.

Conclusion

Tungsten carbide remains the material of choice used in stamping press tools because it has supreme strength, wear resistance, thermal stability, and dimensional accuracy. It is a crucial component of contemporary manufacturing industries because it can operate effectively even in extreme conditions. Through the selection of tungsten carbide, the manufacturers guarantee an increased productivity, extended life of a tool, and an increase in the overall quality of stamped components.